- QT4-15B Automatic Block Making Machine

-

Till now, our automatic block making machine is available with QT4-15B series, QT4-15C series, QT6-15 series, QT6-15B series, QT8-15 series, and QT10-15 series. It has been certified by CE, SGS, TUV, and the like. Our machine has been approved by Bureau Veritas, TUV CERT.

More detailed product information to please download the PDF PDF Download>>

PDF Download>>

Performance:

1. Mainframe

The automatic block making machine applies the high-strength structural steel and special welding technique for its mainframe. The firmness of the mainframe allows the whole machine to come with good rigidity and vibration resistance.

2. Guide Pillar

The guide pillar of this machine applies the ultrastrong special steel. By virtue of the chromate plated treatment, it perfectly resists torsion and abrasion. Additionally, the four guide pillars together with the ultra-long guide bearing make the pressure head and mould move accurately. This moving system adopts the special device that is good for lubrication, thus avoiding abrasion.

3. Material System

The crane of the material machine is controlled by the hydraulic system. That its hopper is connected to the crane by the rubber spring, can offer favourable damping effect while preventing the vibration compaction of the remained materials. In the system, the hopper is equipped with a door which can help realize the uniform material distribution.

4. Material Distributing System

In this system, the material storage and distribution are independent from each other. The material receiving in the material box is accurately controlled. Under the function of the powerful centrifugal force, the material is speedily and evenly distributed.

Specification:

1. QT4-15B Automatic block forming machine Main technical parameters:

| forming machine theoretical data | |||

| Dimension of host machine | 2.44x2x2.6 m | Mixer style | JS500 / JD500 |

| main vibrator style | lower mould vibration | Number of hydraulic vibrator | 0 |

| control style | PLC | forming style | hydraulic |

| Number of motor vibrator | 4 | hydraulic cylinders | 1 |

| Hopper capacity of concrete | 0.6 M3 | feeding style | 360degree revole |

| Moulding area | 800x400 mm | forming height | 40-250mm |

| Moulding period | 15-20 S | vibration force | 42 kn |

| forming blocks per mould400x200x200mm | 4 | The size of the pallet | 1010x550 mm |

| Weight of the host machine | 15T | ||

| Water and Voltage | |||

| Genetal water Consumption | 5.5T | Voltage | 380 V |

| Power | 27 kw | . | . |

|

Simple line Uesd Area |

|||

| A.Production area excluding concrete mixing zone | M2 | 400 | |

| B. Concrete mixing zone area | M2 | 100 | |

| C.Finished product Warehouse | M2 | 600 | |

| E.Raw material storage | M2 | 500 | |

| F.office | M2 | 100 | |

| G.Total area | M2 | 1700 | |

| pratical workers arrangement | |||

| control/operation | 1 | wheel loader | 1 |

| forlift | 2 | repaire/maintain | 1 |

| sum | 5 | ||

| Size(LxWxH) | Pcs/Mould | Pcs/ Hr | Pcs/ 8 Hr | m3/year |

| 400X100X200 | 8 | 1200-1920 | 9600-15360 | 27648-36864 |

| 400X150X200 | 6 | 900-1440 | 7200-11520 | 31104-41472 |

| 400X200X200 | 4 | 600-960 | 4800-7680 | 27648-36864 |

| 400X250X200 | 3 | 450-720 | 3600-5760 | 25920-34560 |

| 200X100X60 | 16 | 1920 | 15360 | - |

| 200X163X60 | 8 | 1200 | 9600 | - |

| Can make all kind of hollow and solid and paver block | ||||

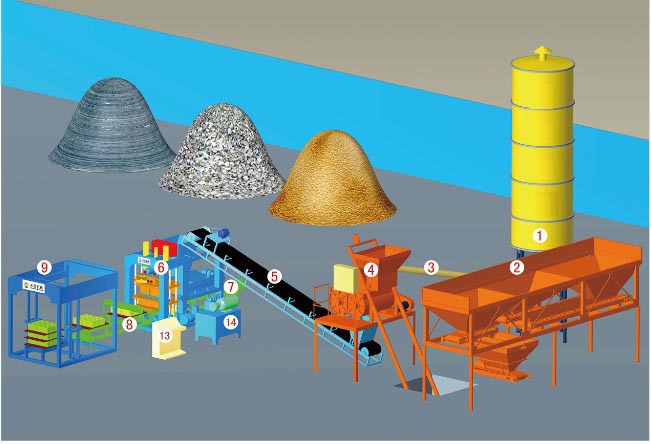

3. How does Automatic Block Making Machine work?

1. Screw Conveyer (Optional fitment): loading bins of the instrument for transporting Fly Ash from the silos(optional fitting) or cement hopper (optional fitting) to the Batching Plant.

2. Batching Plant: It consists of three loading bins and one weighing bin. It also contains blet conveyers to convey materials from loading bins to weighing bin. Batching and weighing is done by PLC control. We can load three different types of material into the loading bin.

3. Conveyer Belt: When the Batching plant's weighing bin trips according to the PLC control, the material comes to this conveyer belt. Then conveyer belt carried materials to the Mixture Machine.

4. Concrete Mixture Machine: All the ingredients are mixed in this mixture machine. Mixing time and speed is controlled by PLC. The inbuilt water pump adds water to the mixer automatically, as per requirement.

5. Block mold machine: This is key of the production line. It can press the mixed material. So it can make various hollow block, solid brick, paver brick and kerbstone.

6. Stacker: Stacker is used to lay the block automatically, which is high-efficient and labor saving.

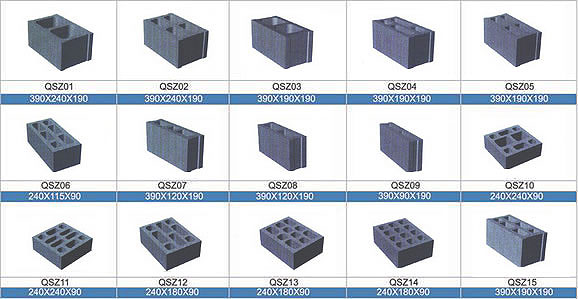

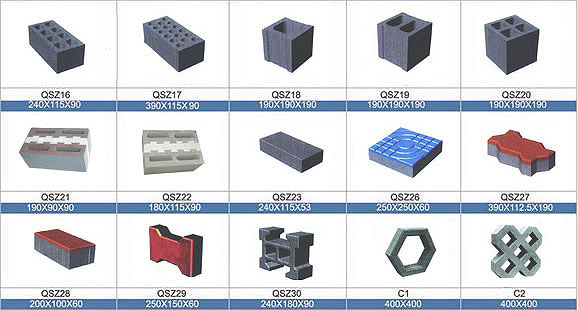

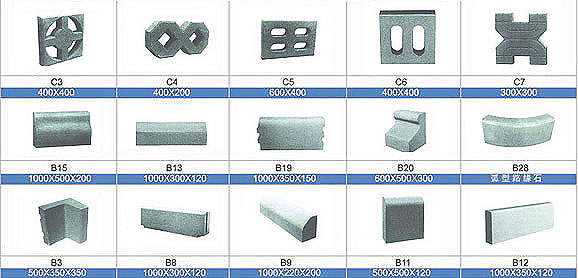

4. Block and Brick Models:

Related Products

- XBS/DXBS Fine Stone Concrete Pump

XBS/DXBS series products are a kind of mortar conveying equipments specially developed acco...

- Mobile Concrete Batching Plant

Mobile concrete mixing plant with running system is special construction concrete equipment...

- Weighing System

Aggregate weighing system is realized by aggregate batching machine. In small concrete batc...

Get price and support, find the working site in your country !

Get price and support, find the working site in your country !

If you have any problems or questions about our products or need our support and assistance, please feel free to write us. We will reply to you within 24 hours, and never reveal your information to the third party. Thank you!

Products

- Concrete Batching Plant

- Belt conveyor type concrete batching plant

- Skip hoist type Concrete Batching Plant

- Mobile Concrete Batching Plant

- Modular Concrete Batching Plant

- Modular Full-weighing stabilized soil Mixing station

- Concrete Mixer

- SICOMA Double Shaft Concrete Mixer

- JS series Concrete Mixer

- MP Planetary Concrete Mixer

- JZ series Concrete Mixer

- JZD Diesel Driven Concrete Mixer

- European Tech.Twin shaft Concrete Mixer

- Concrete Mixer with Pump

- Self-loading Mobile Concrete Mixer

- Concrete Block Making Machinery

- HM-150T Paver Block Making Machine

- HM-150TB Hydraulic Paving Block Machine

- QT4-15C Automatic Block Making Machine

- QT4-15B Automatic Block Making Machine

- QT6-15B Automatic Block Making Machine

- QT8-15 Automatic Block Making Machine

- QT10-15 Automatic Block Making Machine

- QT9-15 Automatic Block Making Machine

- Concrete Delivering Plants

- 1.6cbm Concrete Mixing Truck

- 2cbm Concrete Mixing Truck

- 3cbm Concrete Mixing Truck

- 4cbm Concrete Mixing Truck

- 6cbm Concrete Mixing Truck

- HBT/DHBT series Concrete Pump

- Small and Medium Concrete Pump

- XBS/DXBS Fine Stone Concrete Pump

- Cement Mortar Foam Machine

- LSY series Screw Conveyor

- PLD Concrete Batching Machine

- Cement Silo